Brass Fetcher Ballistic Testing

Extreme Weather Performance of the 22 LR Federal 36gr Champion PLHP

Introduction

We cannot choose the time or place that an emergency situation takes place. If your emergency finds you in a situation where you must hunt small game animals for food, a 22 LR firearm is indispensable. The ammunition for the 22 LR is lightweight, cheap and ‘good enough’ to harvest game animals with significantly high caloric content. It is marginally effective against hostile humans but in survival situations, your first interest is surviving and coming out on top comes in a distant second to simply making it through your ordeal.

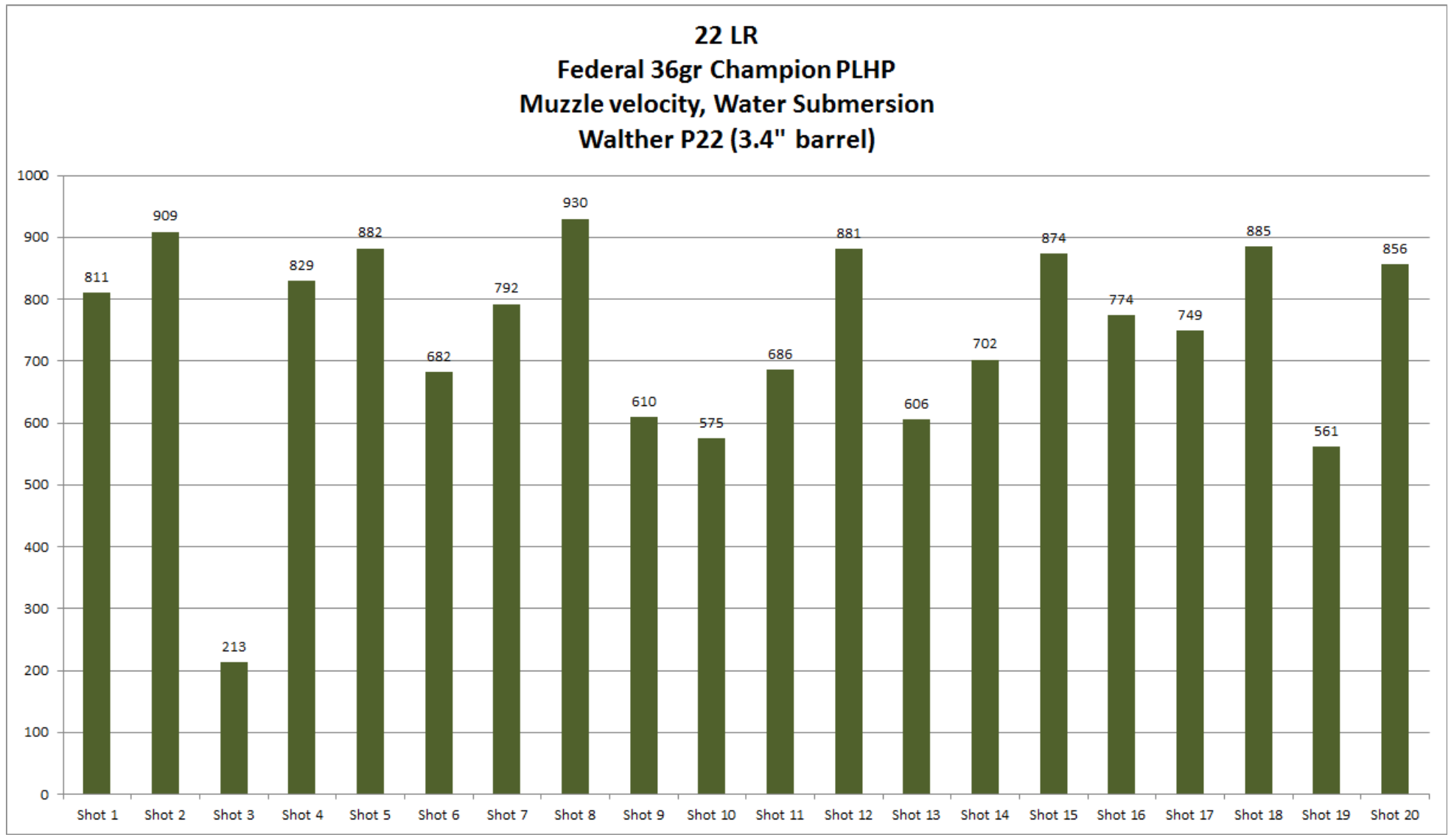

To this end we can expect that the survivor could find themselves in harsh environmental extremes. Just as we are affected by the environment, the equipment that we carry is also subject to the harsh impact of nature’s forces. Most ammunition features a tight fit between the mouth of the cartridge and the bullet. This makes a good enough seal to keep out water during brief contact such as a rain storm or brief submergence. But what happens if the situation dictates that you stay in the water for an extended period of time? Are you going to unload your gun and leave the ammunition behind or will you take it with you? Naturally, you will take the ammunition with you. Ammunition can be made suitably waterproof by the addition of a sealant to the primer and case mouth. This is one advantage of the 22 LR (or any other rimfire) for survival – the priming compound is located inside of the cartridge so there is no possibility of water leakage through the primer hole. You only have a single point of failure with rimfire cartridges in this regard – sealant need only be applied to the cartridge case mouth.

A cartridge can still fire if the propellant bed is partially wetted by water infiltration but this is a sub-par situation at best. The muzzle velocity will be erratic and sometimes too low to cycle an automatic action or to hurt the target it was intended for. If you are shooting at any distance, the variable muzzle velocity will make your rifles zero essentially worthless because each bullet will drop different distances at the same range to the target.

Extreme temperatures have an adverse effect on cartridge performance with extreme cold weather being more detrimental than extremely hot weather. Since there is a conceptual relationship between propellant deflagration and the Ideal Gas Law, you can see the effect of the initial temperature of the propellant bed upon the peak pressure inside of the chamber:

PV = mRT

Since we are talking about concepts, we will disregard the m and R terms and end up with:

PV = T

With the same volume (since we’re talking about the effect of increasing temperature inside of the same cartridge), we have:

P = T/V

So, the higher the initial temperature of the propellant, the higher the pressure inside the case. This will increase the force acting on the bullet, which will push the bullet to a higher velocity. Higher temperature is not usually a problem because the velocity increase isn’t large enough to matter unless you are striving for very high precision, long range rifle fire.

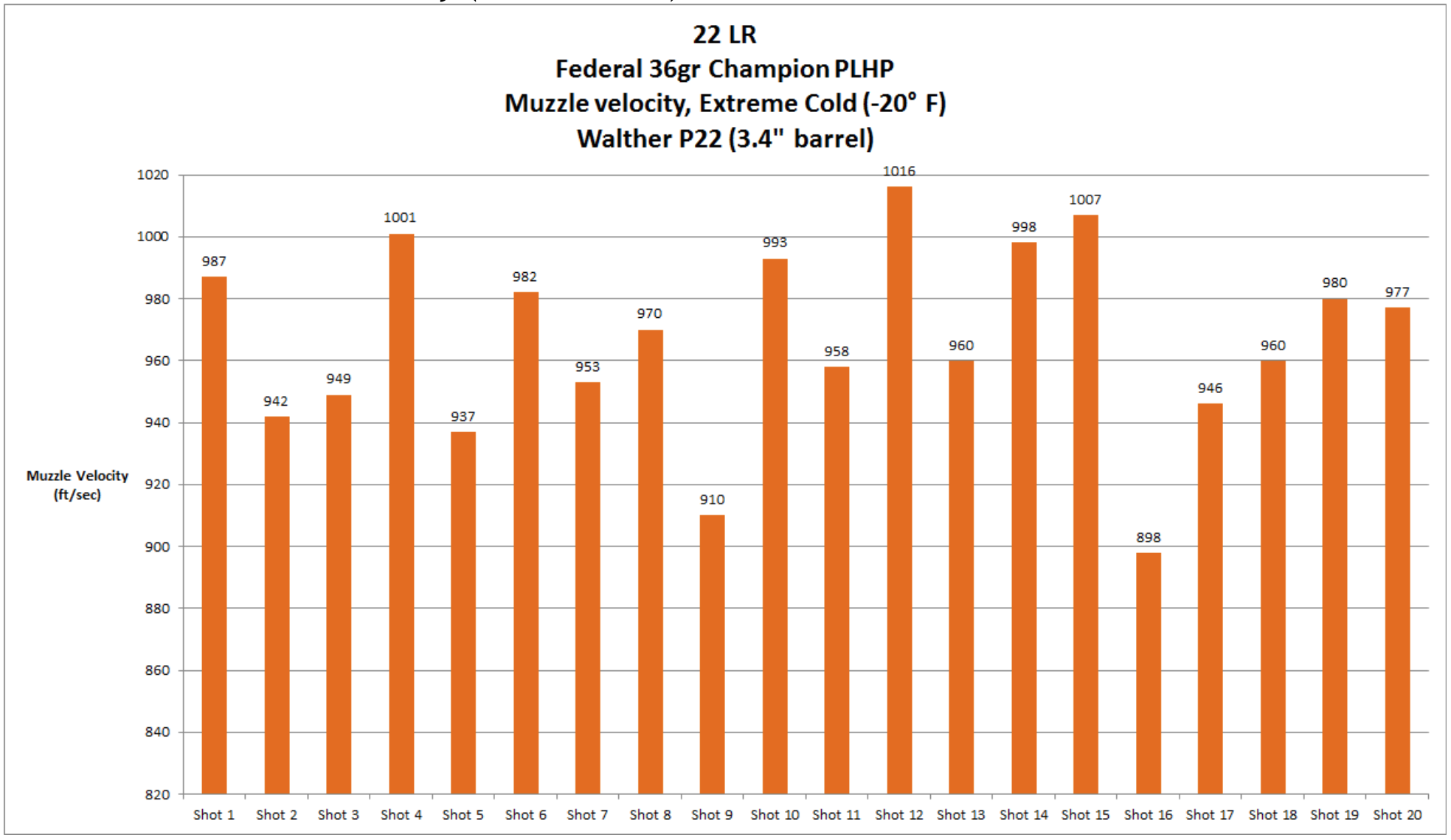

The situation is much different when discussing extremely low temperatures. Small arms propellant contains nitroglycerine, which has a freezing point of 55 degrees Fahrenheit. This means that the cellulose grains will become brittle and then crack as the nitroglycerine contained within the propellant grain cracks. Propellant grains that crack will expose a larger surface area which increases the rate at which the propellant burns. Back to the Ideal Gas law analogy:

PV = mRT

Selecting the proper propellant burn rate (done by manufacturers when generating load data) involves matching the weight of the bullet and the shot-start pressure (determined by many factors like bullet crimp and bullet seating depth in the cartridge case) with the burn rate of the propellant. If the propellant burns more quickly than designed, there will not be sufficient time for the bullet to move down the barrel and subsequently open up the volume that would keep the pressure below a safe limit:

P = T/V

If the volume is smaller, the pressure will be larger and the temperature will be larger (because propellant will deflagrate at a higher temperature as the pressure goes up).

This is why the cold weather performance of cartridges and our knowledge of this is so critical. Not only can performance be adversely affected by extremely cold weather but safety can be affected as well. As the pressure increases, the burn rate will increase and this will increase the pressure further. If the bullet is not far enough down the barrel (large enough volume) then a ‘mechanical detonation’ can occur as both the propellant and firearm explode.

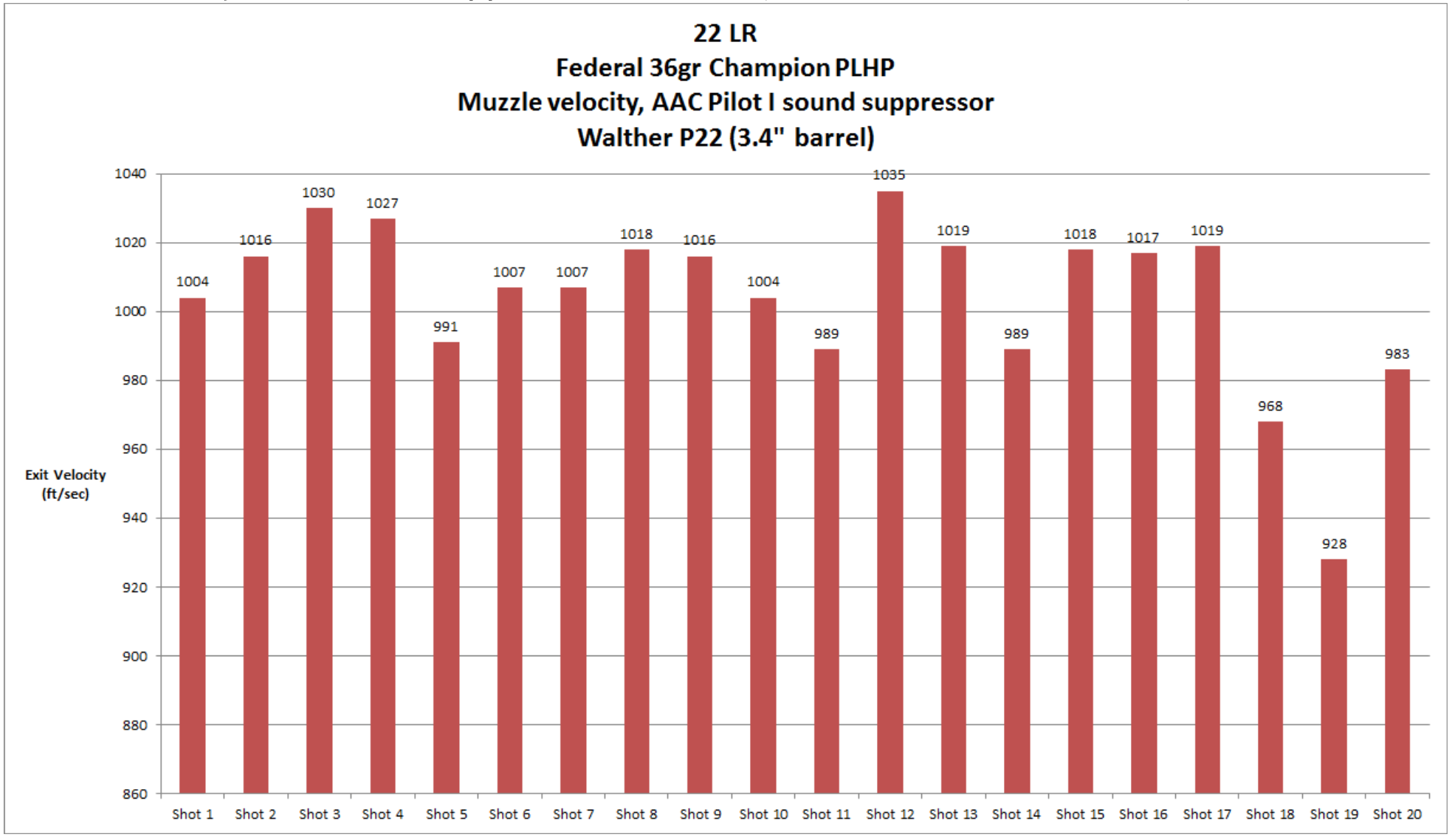

An item that is often discussed is what effect the addition of a sound suppressor has on the muzzle (or exit) velocity of a firearm. We know that the longer the barrel is, generally the faster the bullet will be traveling when it exits the muzzle of the firearm. This is because the propellant contained within is still burning in a smaller volume than if the propellant was dumped into a larger space such as a sound suppressor and of course dumped into the largest volume of the them all – the open atmosphere. Naturally, the function of a sound suppressor is to greatly reduced the audio signature of a firearm firing but it has the side effect of reducing the muzzle flash, the blast that can disturb the vegetation around the shooter and possibly increase the velocity of the bullet as it emerges out of the sound suppressors outlet hole.

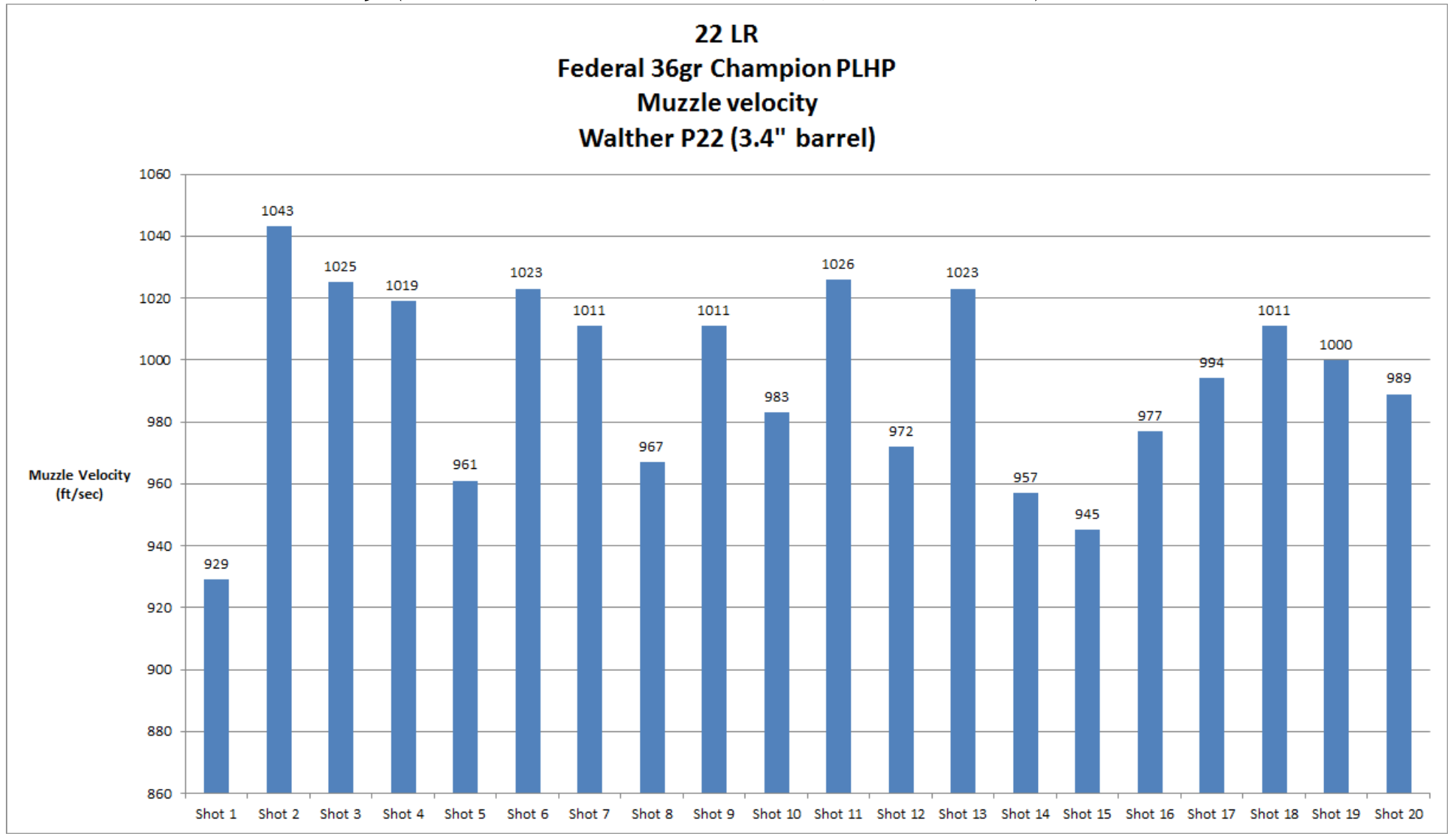

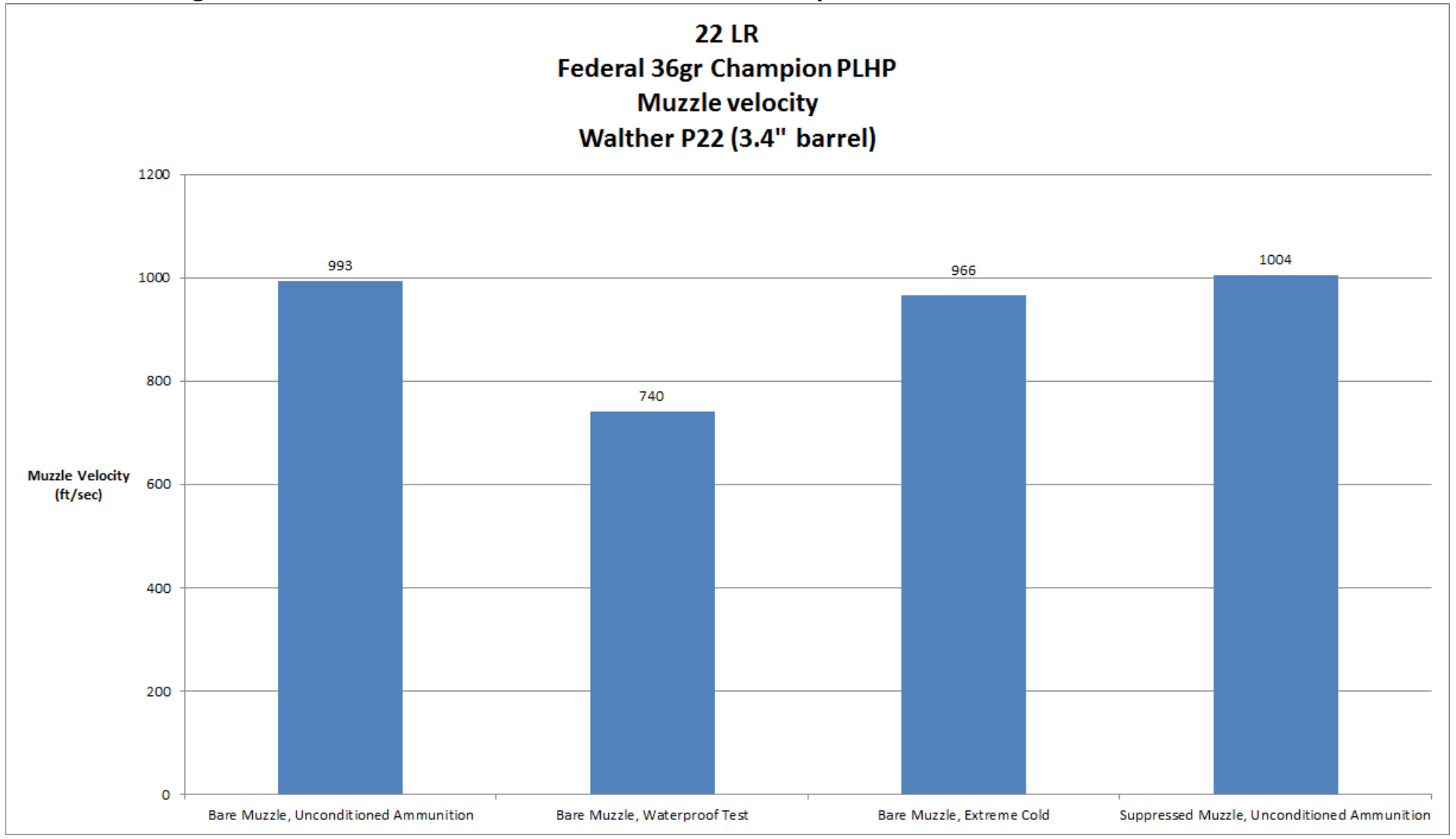

All shots were shot at 10 feet distance from the chronograph with a Walther P22 with 3.4” barrel length. The first string of (20) shots was a baseline set with no muzzle attachment on the firearm. The second string of (20) shots was shot with an AAC Pilot I sound suppressor threaded onto the muzzle of the Walther. The third string of (20) shots was fired with a bare muzzle and the ammunition having been placed in a -20 degrees Fahrenheit atmosphere for 6 days prior to the shooting event. This ammunition was removed from the freezer and shot immediately in the test event. The fourth and final string of (20) shots was fired with a bare muzzle and the ammunition having been subjected to the United States MIL-STD-810 ‘30 minute submersion’ waterproofness test. This ammunition was shot immediately upon removal from the immersion tube.

Figure 1: Walther P22 without Sound Suppressor

Figure 1: Walther P22 without Sound Suppressor Figure 2: Walther P22 with AAC Pilot I Sound Suppressor

Figure 2: Walther P22 with AAC Pilot I Sound SuppressorResults

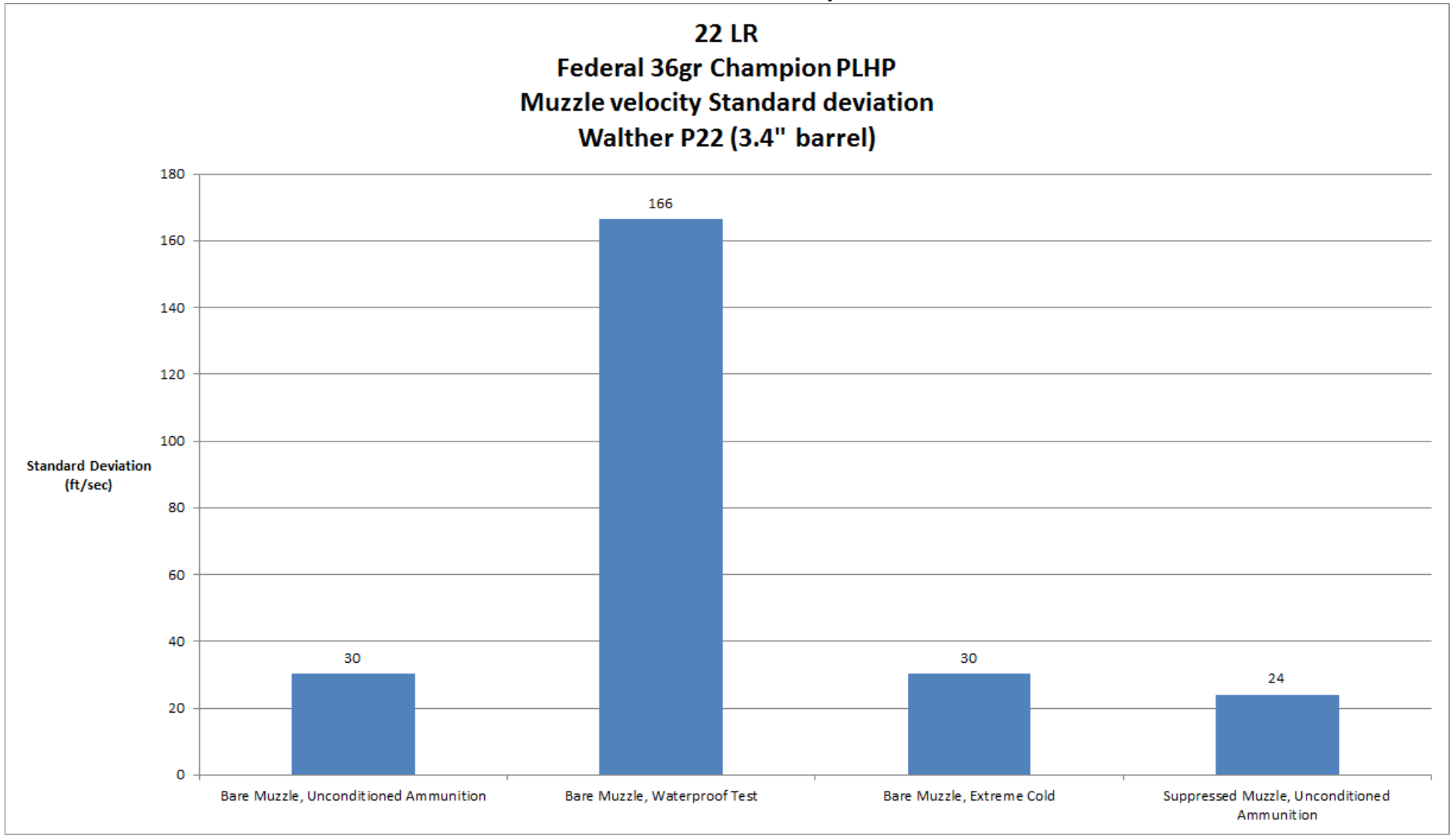

We see a standard deviation in this shot sequence of 30 ft/sec.

The standard deviation from the Sound Suppressor group was lower, at 24 ft/sec.

The standard deviation for the Extreme Cold group was 30 ft/sec — the same standard deviation as the unconditioned group. The tested ammunition demonstrated exceptional extreme cold performance.

Water intrusion was more of an issue with this cartridge. Shot 3 was a squib load and was not powerful enough to cycle the action. Variable velocity was the norm for this shot group.

The highest average velocity was seen with the Extreme Cold group. This is reasonable since the cold can freeze the nitroglycerine and create a greater surface area on the propellant flakes, which will increase the burn rate. The tested ammunition did an excellent job of controlling the propellant burn rate and kept the muzzle velocities remarkably consistent.

The cartridges were suitably consistent when they were not infiltrated by water — temperature was not an overwhelming factor affecting repeatability.

Summary

The Federal 36gr Champion PLHP showed suitable reliability for inclusion in your survival kit. It functioned reliably after passing the MIL-STD-810 waterproofness test and showed a remarkable lack of variability after being exposed to a -20 degree Fahrenheit environment. This temperature was selected because it represents the coldest average temperature in northern Alaska during the winter — a magnitude of cold that few of our localities can begin to approach.

As popular lore has it, the shots with the sound suppressor fitted did indeed feature an 11 ft/sec increase over the average bare muzzle shot. This is insignificant in terms of terminal ballistics but it should be comforting to the shooter to know that the suppressor confers a slight increase in muzzle velocity when compared to the bare muzzle.

Tested elsewhere by Brass Fetcher Ballistic Testing, this bullet did not expand in ballistic gelatin when shot from a Walther P22. If the propellant were replaced with a faster burning pistol propellant, there is a good chance that the 3.4” barrel of the Walther would generate enough velocity for the bullet to expand and penetrate to a respectable distance out of the handgun.

In all, this cartridge should prove acceptable for use in a survival situation — especially if you take it upon yourself to apply cartridge sealant to the casemouth to avoid water infiltration. When shot from a 22 LR rifle, this cartridge is suitable for self-defense due to the higher muzzle velocity.

Video footage of the test event can be viewed here.